Low&Slow

Ancora imparo

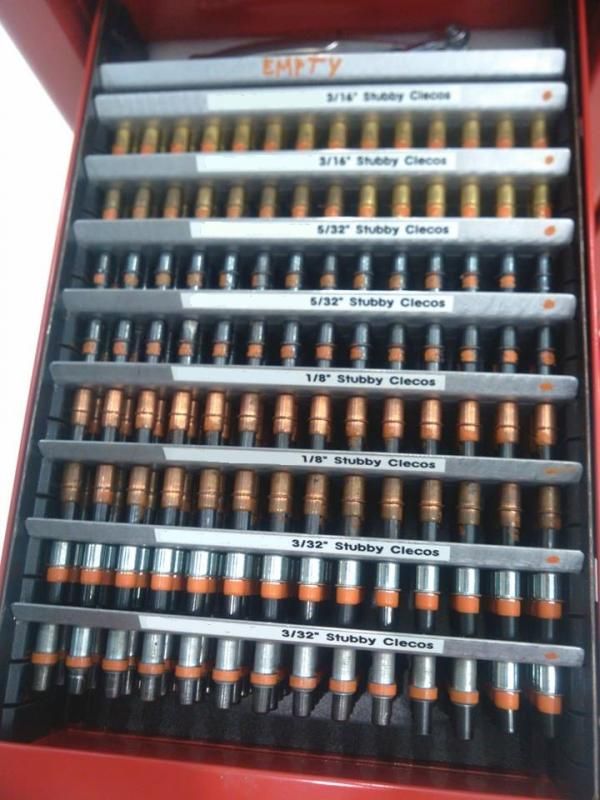

Here's a few pics of how I keep my Clecos organized and stored at work.

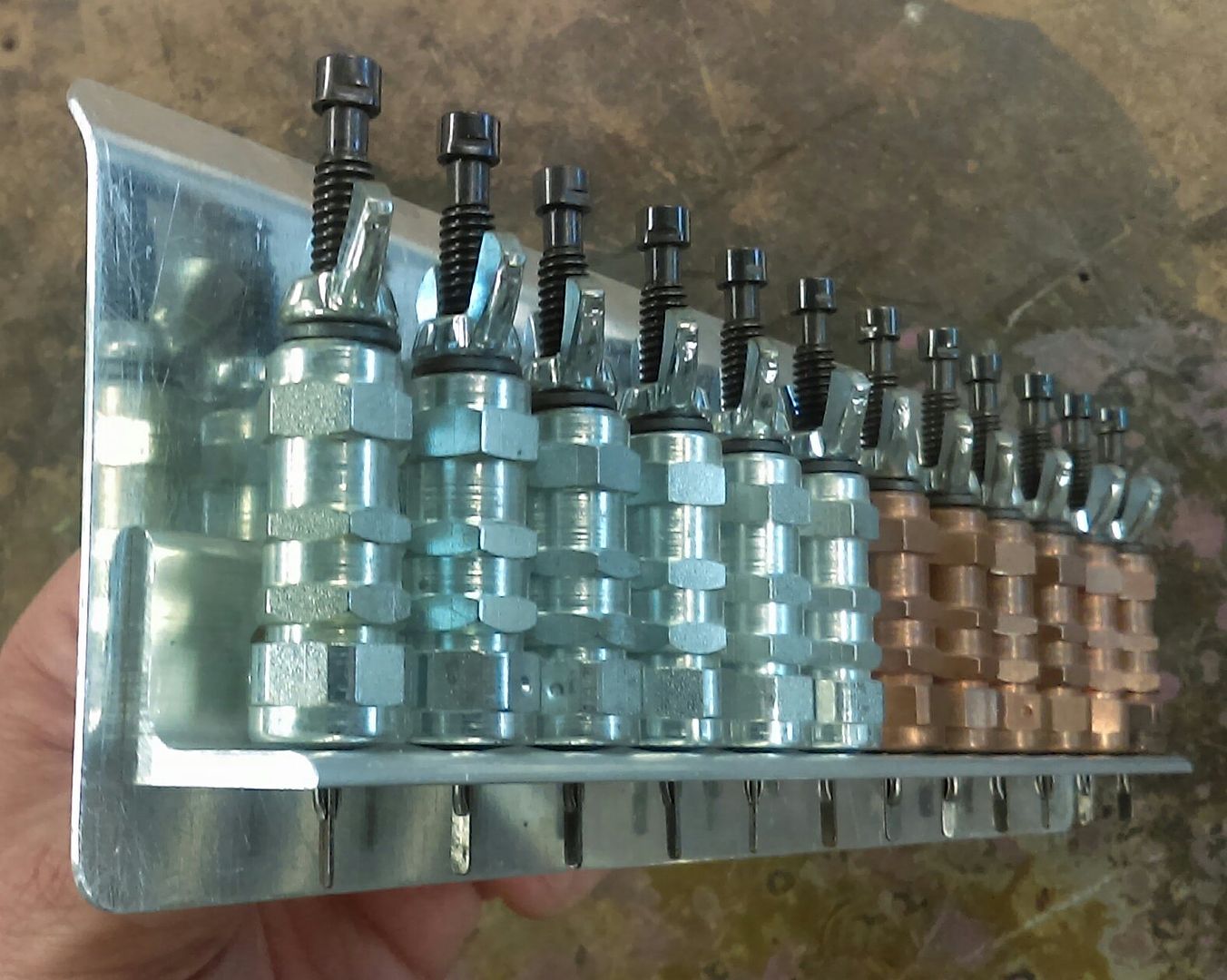

I used drawer dividers and drilled the appropriate sized holes, labeled them, loaded them with clecos and put them in the drawer. I can remove an entire divider and take it with me to where I am working. This arrangement is portable, convenient, saves space, keeps all my clecos together when I'm working and allows me to see instantly if I don't have all of my clecos accounted for after a job and how many are missing.

If you don't have drawer dividers, they're pretty simple to fabricate.

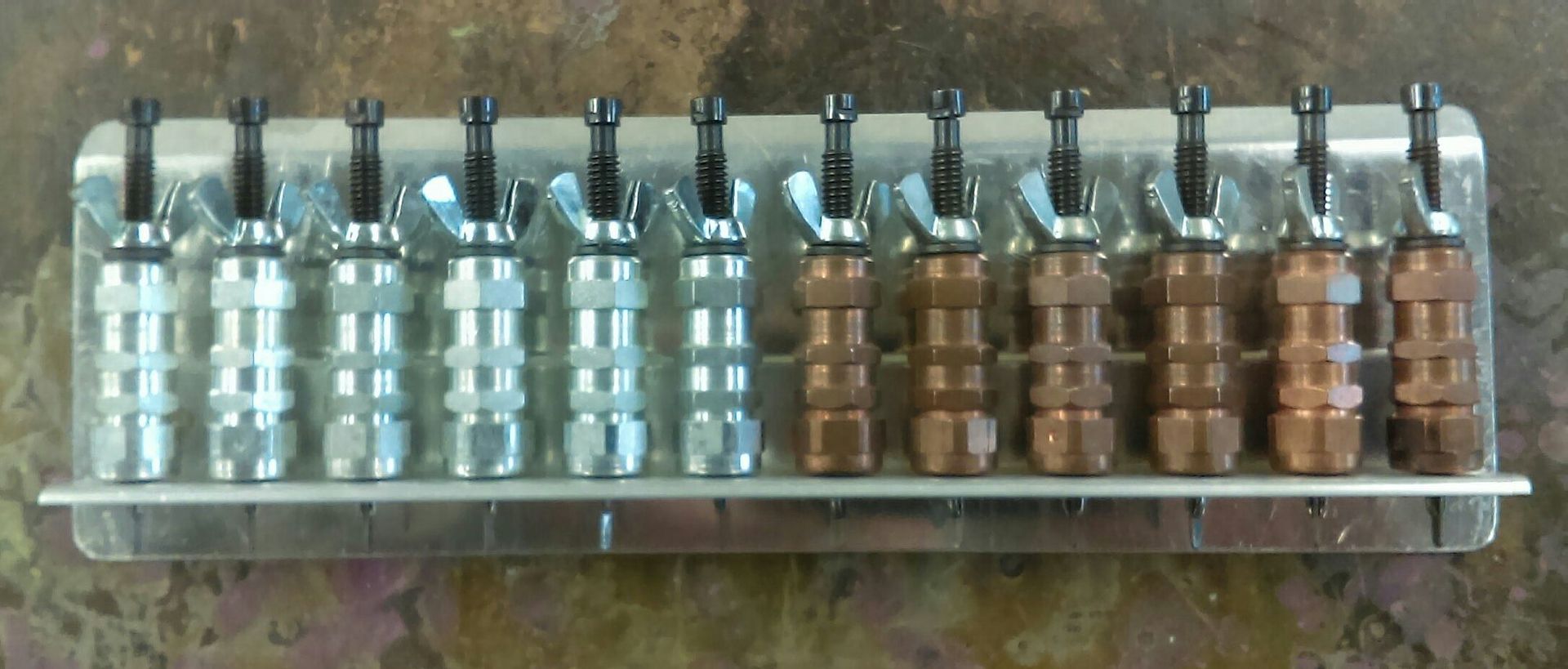

Standard Clecos:

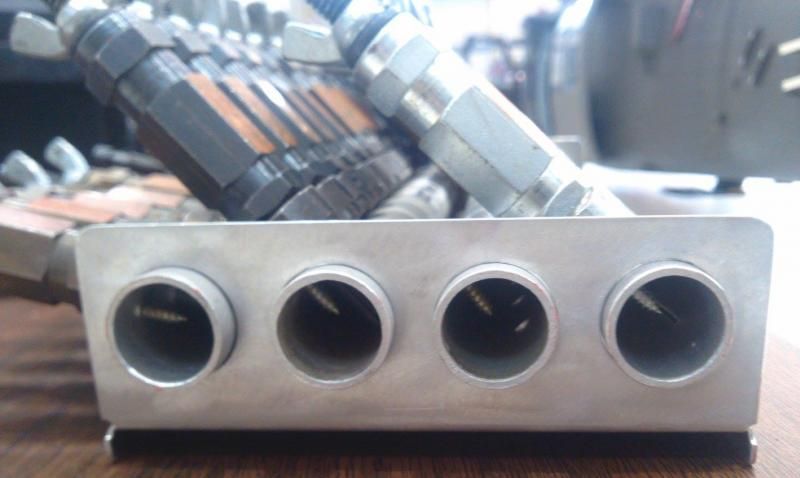

Backside/underside of a divider:

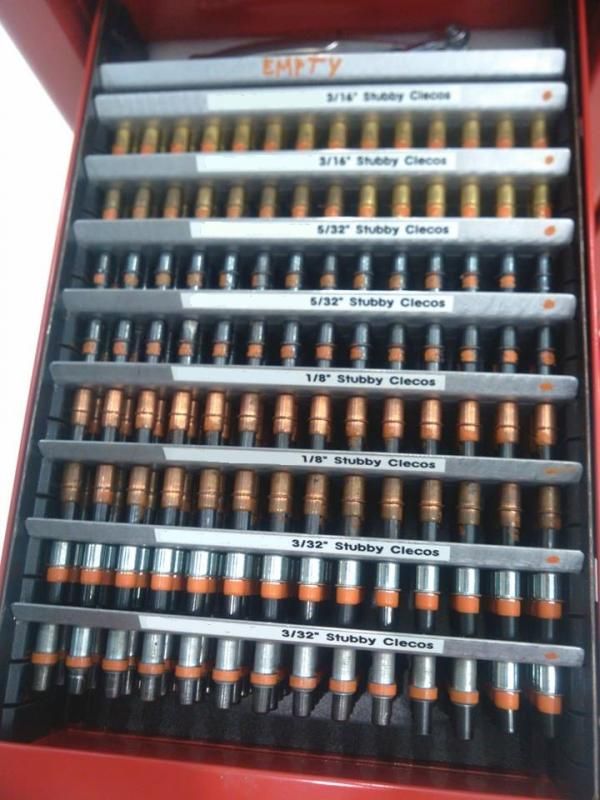

Stubby Clecos:

I used drawer dividers and drilled the appropriate sized holes, labeled them, loaded them with clecos and put them in the drawer. I can remove an entire divider and take it with me to where I am working. This arrangement is portable, convenient, saves space, keeps all my clecos together when I'm working and allows me to see instantly if I don't have all of my clecos accounted for after a job and how many are missing.

If you don't have drawer dividers, they're pretty simple to fabricate.

Standard Clecos:

Backside/underside of a divider:

Stubby Clecos: