Re: Questions for A&P about Cherokee 100 Hour/Annual Inspect

Non-sealed bearings/bellcranks/hinges etc will be lubricated per the aircraft-specific lubrication chart in the maintenance manual. Pulleys will be checked for freedom of movement (a seized pulley allows the cable to slide over it and deepen the groove, and should be replaced). Cables are visually checked for general condition (i.e. no cuts, fraying), attachment points are properly secured with cotter pins and turnbuckles are properly safety-wired (both free ends of the safety wire must end with a minimum of four turns around the turnbuckle barrel).

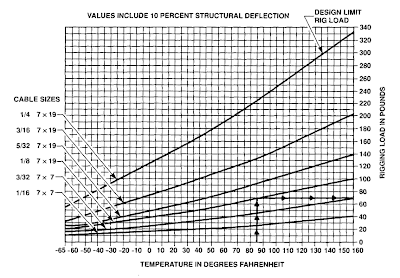

Cable tension is a big deal and the flight control system is visually observed while the controls are manipulated. If the tension in the cables is too loose, they can jump the pulley grooves (not something you want happening in flight). If it's too tight however, the controls will be difficult to move, the system will bind up and the cables will wear excessively and cut into the pulleys. Compounding the problem is the fact that the tension varies naturally as the steel cables expand and contract with temperature, so a rigging load chart must be consulted to find the desired cable tension based on the current temperature and cable diameter. The cable can then be checked with a tensiometer gauge and compared against the desired value. Further complicating the problem is that old tensiometers don't have multiple scales (for different diameters) so a 2nd table must be used to convert the indicated tension on the gauge to the actual value (and sometimes a specific riser attachment must be used for that cable size). If you need to change the tension the safety wire is cut, the turnbuckle is rotated appropriately (making sure not to expose more than 3 threads on each side) and after being absolutely sure the tensiometer is reading the correct value the turnbuckle is finally re-safetied using one of the approved methods.

Rigging Load Chart:

Simple cable tensiometer & conversion table:

Larger images available

here.

Finally I don't have a lot of experience with Cherokee 140s, but my old flight school had two Warriors and an Archer. There is a raised carpeted center pedestal in the middle of the floor that the Johnson bar flap handle sits on, and the whole thing is a removable access panel. I can't remember why but it was a PITA for some reason and other mechanics there either weren't removing it during 100 hours or were only partially removing it. Well one day I decided to take the whole thing off and have a look, and I couldn't believe what I found. The flap cables had jumped their pulleys and wrapped around the elevator cables, and they were grinding against each other. It was appalling to think that the problem could have continued uncorrected had I not gone out of my way to try and get a better look at the system, so I really recommend trying to go above and beyond to get the most thorough look at everything as you can if there's any doubt.

Take the above with a grain of salt, I was not able to stay with the company long enough to complete the required training for the A&P and haven't worked in aviation maintenance in several years (although I find myself day dreaming about the good old days more and more lately). But hopefully this is more than you wanted to know on the subject.

(Source: Dale Crane, "Airframe, Volume 1: Structures." ASA Aviation Maintenance Technician Series)