You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CH-47 Chinook blade repair

- Thread starter Low&Slow

- Start date

Low&Slow

Ancora imparo

Haha!

I always put a smiley face on each side after the blade taps out okay and passes my inspection. It helps me keep track of which blades still need to be tapped and inspected and which ones are SAT. If I suspect delamination or see any other problems, I circle them in red.

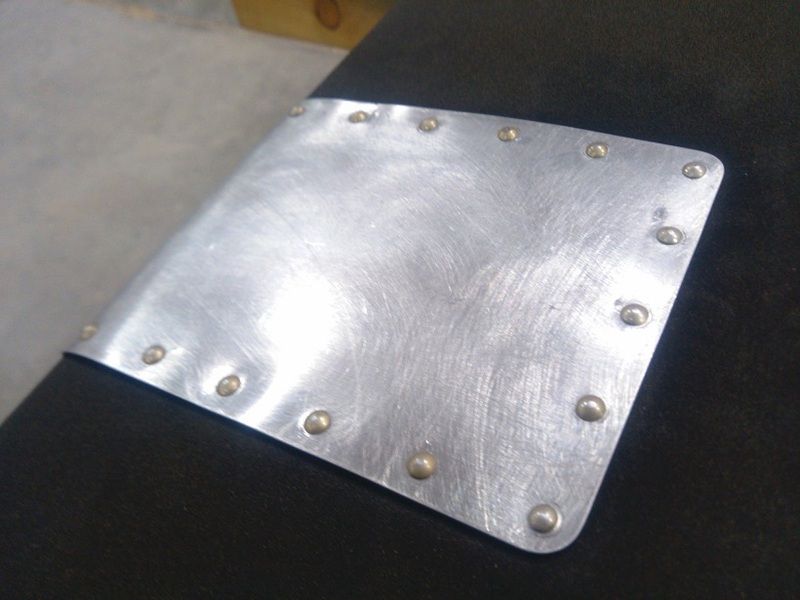

The repair patch isn't actually a repair patch, it's a prank. I made it out of 0.032 2024-O and 4-2 "A" Universal head rivets, it just slips over the leading edge. The shop head of the rivets were countersunk so that the "patch" would sit tight up against the blade. I also took a headset and a hammer and lightly tapped each rivet down on my workbench to give it a slightly dimpled look to help the repair look more authentic/legit.

I got a coworker to play along with me to help sell it. Our backstory was that a mechanic from another group accidentally hit the blade with a cart and created some minor damage, but it was within the acceptance criteria and could be repaired. So I sent him out to put 9309.3 on it (basically plastic filler like Bondo), but he was taking longer than I expected. When I went out to check on him and find out why it's taking him so long, this is what I found him working on. He plays along and says that he knows it's an improper repair because he only has one row of rivets and a patch should have at least two rows, but he was getting ready to start a second row when I interrupted him. He's supposed to act completely oblivious that he has just destroyed a $300k main rotor blade and be insistent that he finish adding another row of rivets so he can paint it and proseal it.

We got some pretty amazing reactions from various people. Their reactions ranged from a terrifying look of horror, fear, and nearly fainting to loudly and violently pissed off beyond belief. It was absolutely hilarious to watch!

On hindsight, I wish I had set up a GoPro camera or had another person record it on a smartphone.

I always put a smiley face on each side after the blade taps out okay and passes my inspection. It helps me keep track of which blades still need to be tapped and inspected and which ones are SAT. If I suspect delamination or see any other problems, I circle them in red.

The repair patch isn't actually a repair patch, it's a prank. I made it out of 0.032 2024-O and 4-2 "A" Universal head rivets, it just slips over the leading edge. The shop head of the rivets were countersunk so that the "patch" would sit tight up against the blade. I also took a headset and a hammer and lightly tapped each rivet down on my workbench to give it a slightly dimpled look to help the repair look more authentic/legit.

I got a coworker to play along with me to help sell it. Our backstory was that a mechanic from another group accidentally hit the blade with a cart and created some minor damage, but it was within the acceptance criteria and could be repaired. So I sent him out to put 9309.3 on it (basically plastic filler like Bondo), but he was taking longer than I expected. When I went out to check on him and find out why it's taking him so long, this is what I found him working on. He plays along and says that he knows it's an improper repair because he only has one row of rivets and a patch should have at least two rows, but he was getting ready to start a second row when I interrupted him. He's supposed to act completely oblivious that he has just destroyed a $300k main rotor blade and be insistent that he finish adding another row of rivets so he can paint it and proseal it.

We got some pretty amazing reactions from various people. Their reactions ranged from a terrifying look of horror, fear, and nearly fainting to loudly and violently pissed off beyond belief. It was absolutely hilarious to watch!

On hindsight, I wish I had set up a GoPro camera or had another person record it on a smartphone.

Last edited:

Roger Roger

Bottom of the list

Looks good to me.

bustinminimums

Well-Known Member

"Why do we have a 3 per going on when we try to balance this thing".