jdlilfan

Well-Known Member

I'm not sure if this is the correct thread for this or if it needs to be in technical?

Anyway, I have started to slowly restore a 1966 Garrett GTP70-52 turbine engine. All I have is a good working knowledge of turbines, working knowledge of this engine (from the shop that I bought it from), and a photocopied military MX manual that is missing some pages. I have no history of the engine other than it was crated from the US military and it looks to be pretty low time. Almost all the components are shiny and clean (other than some dust). The engine is missing the FCU, starter, and fuel nozzle. I have found a replacement fuel nozzle. I will most likely use diesel parts for the FCU and bypass the bleed air mixing. Not sure on a starter?

There is little to no information out there on this particular engine and little to no resources for parts. Anyway I was hoping that someone on this board had some experience or could point me in the right direction on certain parts I need.

First off, I am starting with acquiring instrumentation. There is a Tach generator installed on the accessory drive. From that is a two plug connector. However the used/surplus tach gauges I have seen have 5 or 6 plug connectors. Are the two plugs just positive and negative?

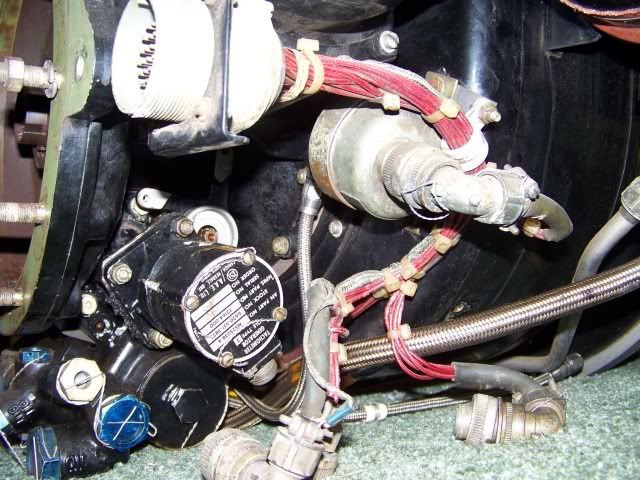

Here is the tach gen:

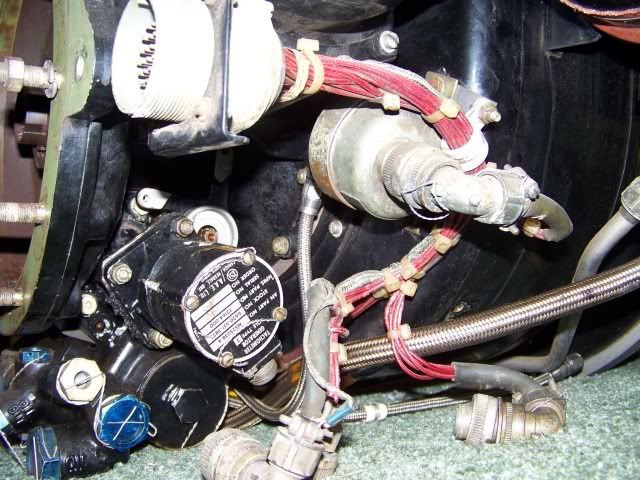

Here is the plug:

Also the engine does not turn by hand. It will turn slightly then feel like it is caught. Like there is some shaft play? I am thinking this is because it is a direct drive to the gearbox and requires some force to get it to move? My grip doesn't seem to generate enough torque to twist the shaft and the hot side of the turbine is a little to small to get my fingers in there for grip. Am I correct in this assumption?

As for starting work on this, I was thinking about taking off the hot section and inspecting it. That way too I can get some leverage to turn the turbines and get a feel for the bearings. Also I will start cleaning out the oil system since there is white flaky goo in the oil tank (I'm thinking a preservative?). A friend said to clean it with Tranny fluid? I found some lucas oil treatment that looked suitable but was wondering what mechanics use to flush out a turbine oil system?

I was going to ask the shop I bought it from but they are not too eager to help due to liability issues I guess? Not sure, they just aren't eager.

Thanks for the help! This will be a long project. I'm in no hurry. Just something to tinker with.

Anyway, I have started to slowly restore a 1966 Garrett GTP70-52 turbine engine. All I have is a good working knowledge of turbines, working knowledge of this engine (from the shop that I bought it from), and a photocopied military MX manual that is missing some pages. I have no history of the engine other than it was crated from the US military and it looks to be pretty low time. Almost all the components are shiny and clean (other than some dust). The engine is missing the FCU, starter, and fuel nozzle. I have found a replacement fuel nozzle. I will most likely use diesel parts for the FCU and bypass the bleed air mixing. Not sure on a starter?

There is little to no information out there on this particular engine and little to no resources for parts. Anyway I was hoping that someone on this board had some experience or could point me in the right direction on certain parts I need.

First off, I am starting with acquiring instrumentation. There is a Tach generator installed on the accessory drive. From that is a two plug connector. However the used/surplus tach gauges I have seen have 5 or 6 plug connectors. Are the two plugs just positive and negative?

Here is the tach gen:

Here is the plug:

Also the engine does not turn by hand. It will turn slightly then feel like it is caught. Like there is some shaft play? I am thinking this is because it is a direct drive to the gearbox and requires some force to get it to move? My grip doesn't seem to generate enough torque to twist the shaft and the hot side of the turbine is a little to small to get my fingers in there for grip. Am I correct in this assumption?

As for starting work on this, I was thinking about taking off the hot section and inspecting it. That way too I can get some leverage to turn the turbines and get a feel for the bearings. Also I will start cleaning out the oil system since there is white flaky goo in the oil tank (I'm thinking a preservative?). A friend said to clean it with Tranny fluid? I found some lucas oil treatment that looked suitable but was wondering what mechanics use to flush out a turbine oil system?

I was going to ask the shop I bought it from but they are not too eager to help due to liability issues I guess? Not sure, they just aren't eager.

Thanks for the help! This will be a long project. I'm in no hurry. Just something to tinker with.